Types Of Friction

Friction is a force that resists the relative motion of two objects in contact. It is an essential concept in physics, and its understanding is crucial in several fields, including engineering and mechanics. The study of friction has led to the development of several theories and models that help explain the behavior of objects in contact.

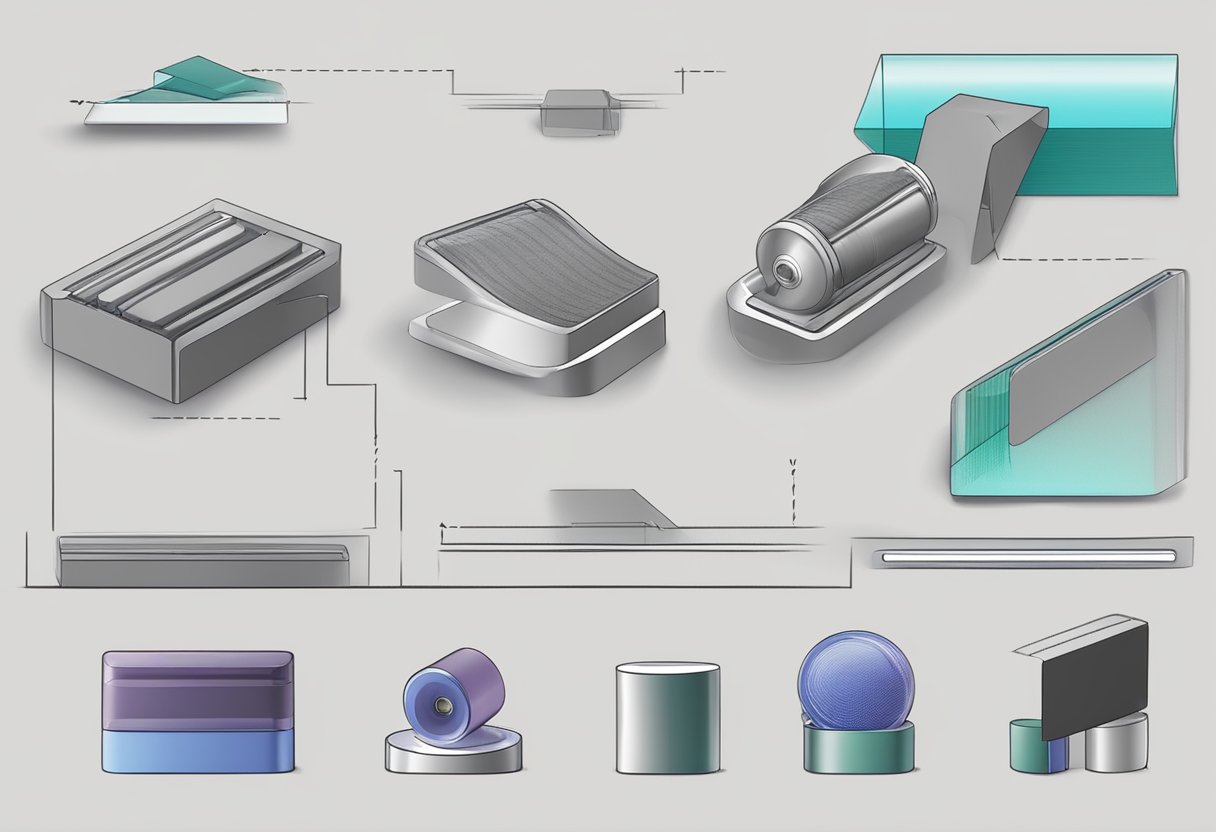

Fundamentally, friction can be categorized into four types: static, sliding, rolling, and fluid friction. Static friction acts on an object when it is at rest and prevents it from moving. Sliding friction occurs when two objects slide against each other. Rolling friction occurs when a round object rolls over a surface, and fluid friction occurs when an object moves through a fluid. The type of friction that occurs depends on the nature of the surfaces in contact, the force applied, and the speed of the objects.

Understanding the different types of friction is essential in predicting and controlling the behavior of objects in motion. It is also crucial in developing efficient machines and devices that can reduce friction and improve performance. In this article, we will explore the different types of friction, their characteristics, and their practical applications.

Key Takeaways

- Friction is a force that resists the relative motion of two objects in contact.

- The four types of friction are static, sliding, rolling, and fluid friction.

- Understanding the different types of friction is essential in predicting and controlling the behavior of objects in motion.

Fundamentals of Friction

Friction is a force that opposes motion between two surfaces that are in contact with each other. It is an essential concept in physics and engineering, as it plays a crucial role in the design and function of various machines and structures. Understanding the fundamentals of friction is important for anyone studying or working in these fields.

Understanding Frictional Force

Frictional force is the force that opposes the motion of an object when it is in contact with another object or surface. It is caused by the roughness and irregularities of the surfaces in contact, which create interlocking between the two surfaces. The force of friction always acts in the opposite direction to the motion of the object.

The magnitude of frictional force depends on several factors, including the nature of the surfaces in contact, the normal force between the two surfaces, and the coefficient of friction. The coefficient of friction is a dimensionless quantity that describes the relationship between the frictional force and the normal force.

Normal Force and Friction

The normal force is the force that acts perpendicular to the surface of contact between two objects. It is equal in magnitude and opposite in direction to the force that the object exerts on the surface due to gravity. The normal force plays a crucial role in determining the magnitude of the frictional force.

The frictional force is directly proportional to the normal force between the two surfaces in contact. This means that if the normal force increases, the frictional force also increases. Conversely, if the normal force decreases, the frictional force also decreases.

In conclusion, friction is a fundamental concept in physics and engineering that plays a crucial role in the design and function of various machines and structures. Understanding the relationship between frictional force, normal force, and coefficient of friction is essential for anyone studying or working in these fields.

Types of Friction

When two surfaces are in contact, they can experience different types of friction. The four main types of friction are Static Friction, Kinetic Friction, Rolling Friction, and Fluid Friction. Each type of friction has its unique characteristics and plays a crucial role in our daily lives.

Static Friction

Static friction is the force that prevents an object from moving when a force is applied to it. It is the friction that must be overcome to start an object’s motion. The coefficient of static friction is a measure of how much force is required to start an object moving. The coefficient of static friction is generally higher than the coefficient of kinetic friction.

Kinetic Friction

Kinetic friction is the force that opposes the motion of an object that is already moving. It is the friction that must be overcome to keep an object moving at a constant speed. The coefficient of kinetic friction is a measure of how much force is required to keep an object moving at a constant speed.

Rolling Friction

Rolling friction occurs when an object rolls over a surface. It is generally less than static and kinetic friction. Rolling friction is why wheels are used on vehicles instead of sliding on the ground. The coefficient of rolling friction is a measure of how much force is required to keep an object rolling at a constant speed.

Fluid Friction

Fluid friction occurs when an object moves through a fluid, such as air or water. It is also known as drag. The resistance to motion is proportional to the viscosity of the fluid and the relative motion between the object and the fluid.

In conclusion, friction plays a crucial role in our daily lives. Understanding the different types of friction and how they work is essential in designing machines and structures that operate efficiently.

Factors Affecting Friction

Friction is an important concept in physics and engineering, as it plays a crucial role in determining the behavior of objects in contact. There are several factors that can affect the level of friction between two surfaces in contact. In this section, we will discuss the most important factors affecting friction.

Surface Characteristics

The nature of the surfaces in contact is one of the most important factors affecting friction. The smoothness or roughness of the surfaces can have a significant impact on the level of friction. When the surfaces are smooth, the friction between them reduces as there is not much interlocking of irregularities. On the other hand, when the surfaces are rough, the friction increases due to increased interlocking of irregularities.

Contact Area and Load

The amount of contact area between the surfaces in contact also affects the level of friction. The greater the contact area, the greater the friction. Similarly, the load or weight of the object also affects the level of friction. The greater the load, the greater the friction.

Adhesion and Roughness

Adhesion is the force that causes two surfaces to stick together. The level of adhesion between the surfaces in contact can also affect the level of friction. The greater the level of adhesion, the greater the level of friction. Roughness is another factor that affects the level of friction. When the surfaces are rough, the friction between them increases due to increased interlocking of irregularities.

In summary, the level of friction between two surfaces in contact is affected by several factors, including surface characteristics, contact area and load, adhesion, and roughness. Understanding these factors is crucial in determining the behavior of objects in contact and designing systems that rely on friction, such as brakes and tires.

Friction in Motion

Friction plays a crucial role in the motion of objects. Understanding the different types of friction is essential in designing and optimizing machines. In this section, we will discuss the various types of friction that come into play when objects are in motion.

Sliding Objects

When objects slide against each other, sliding friction comes into play. Sliding friction is caused by the roughness of the surfaces in contact, and it opposes the motion of the object. The force of sliding friction is proportional to the normal force acting on the object and the coefficient of sliding friction between the two surfaces.

Wheels and Axles

Wheels and axles are commonly used to reduce friction and increase efficiency. A wheel is a circular object that rotates around an axle. When a force is applied to the wheel, the axle rotates, and the object moves forward. The rolling motion of the wheel reduces friction, making it easier to move the object.

Energy Considerations

When objects are in motion, friction causes the dissipation of energy. This energy is converted into heat and sound, which can cause wear and deformation of the surfaces in contact. Elastic deformation occurs when the surfaces are compressed, and the deformation is reversible. However, if the deformation exceeds the elastic limit, the surfaces will undergo plastic deformation, which is irreversible.

In summary, friction plays a critical role in the motion of objects. Understanding the different types of friction can help in designing and optimizing machines. Sliding friction opposes the motion of sliding objects, while wheels and axles reduce friction. Energy considerations are also crucial, as friction causes the dissipation of energy and can lead to wear and deformation of surfaces.

Practical Applications and Control

Enhancing or Reducing Friction

Friction can either be enhanced or reduced depending on the application. Lubrication can be used to reduce friction between two surfaces in contact. This is useful in machinery where the reduction of friction can help prevent wear and tear of the components and allow for smoother operation. Traction is another way to enhance friction. By increasing the force between two surfaces, the friction is also increased. This is useful in situations where grip is needed, such as in tires on a car.

Friction in Engineering and Design

Friction plays an important role in engineering and design. Engineers must consider the direction of friction when designing machinery. If the direction of friction is parallel to the surface, it can cause sliding and wear and tear of the components. However, if the direction of friction is perpendicular to the surface, it can cause the components to lock in place, which can be useful in certain applications.

Metals are commonly used in machinery and can experience high levels of friction. To reduce the friction, lubrication can be used. In situations where lubrication is not possible, such as in a heavy crate being dragged across a concrete floor, the friction can be reduced by using a low-friction material, such as a plastic sheet, between the surfaces.

Friction can also be seen in sports such as hockey. The direction of friction is important in allowing the puck to slide across the ice. The surface of the ice is designed to reduce friction and allow for smooth movement of the puck.

In mechanics, friction can be used to control the movement of objects. By adjusting the direction and force of friction, the speed and direction of an object can be controlled. This is useful in applications such as brakes in a car, where friction is used to slow down the vehicle.

Overall, understanding the different types of friction and how they can be controlled is important in many applications. By enhancing or reducing friction, engineers and designers can improve the efficiency and durability of machinery and equipment.